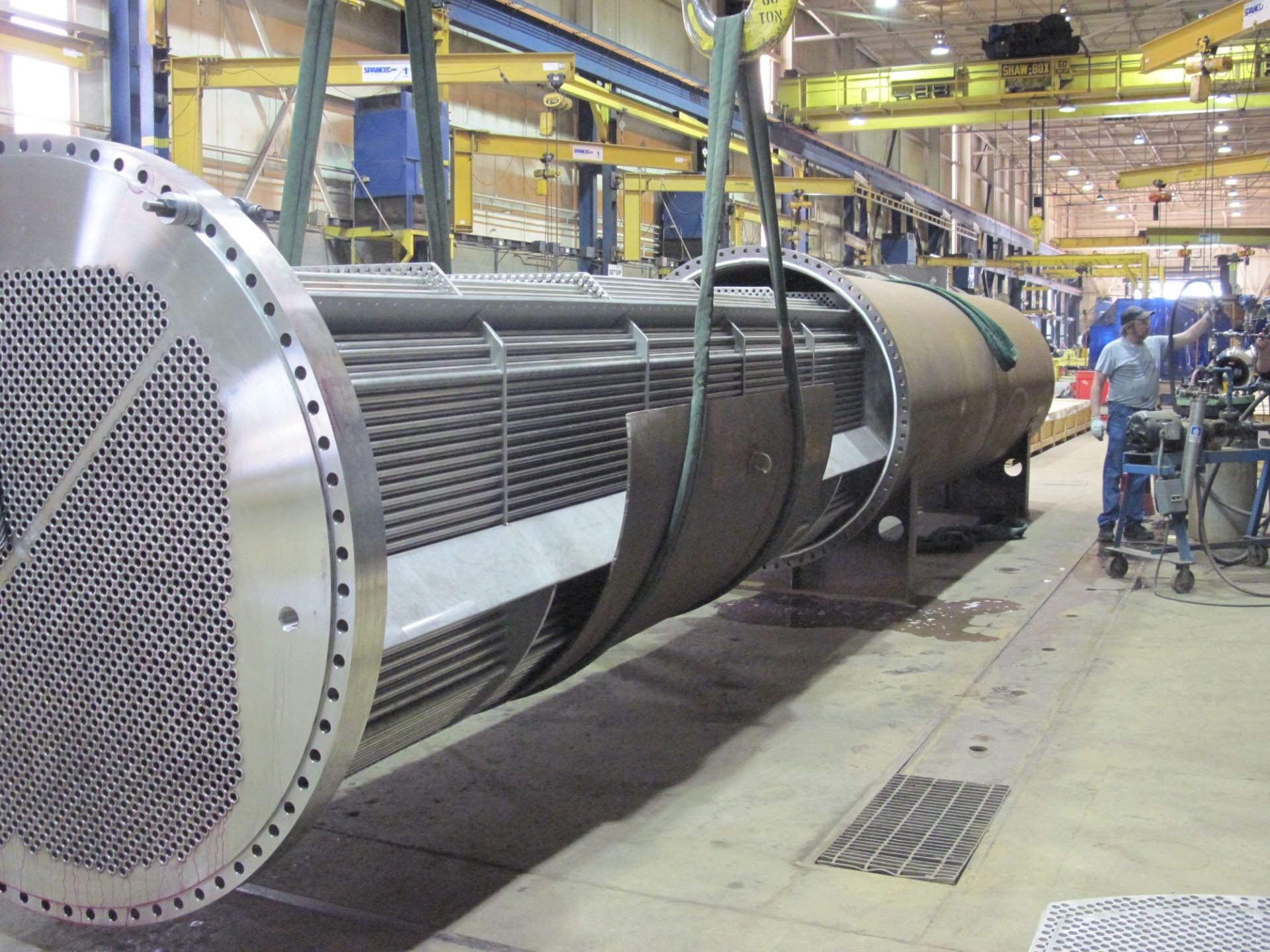

A properly designed Graham Condenser between the process and vacuum producing equipment will yield significant advantages. The use of a process vacuum condenser can permit significant reduction in the size of the vacuum producing equipment. A condenser can recover for reuse valuable product that�s carried from the process with non-condensable gases. It can reduce the amount of wastes produced by the vacuum system and lower the process operating cost. Graham Process Condensers can be designed for a wide variety installation: direct contact or surface type, mounted horizontally or vertically, freeze condensation or conventional condensation type.

Matching the Process Vacuum Condenser with vacuum producing equipment is the best way to meet the process objectives. Graham manufactures both the Process Condenser and the vacuum producing equipment. This single-source responsibility provides a unitized system that is matched to the process.